ABOUT US

Professional Custom Filtration Solution Provider

In-Process Quality Control

We have most advanced equipment and many skillful workers to meet all your demands for filtration components.

Modern processing technology ensures all the specifications more accurate and reliable.

★ Precise cutting machine cut wire mesh into circular or square shapes in different sizes.

★ Resistance welding techniques make solder joint more perfect and firmer.

★ Ultrasonic cleaning system guarantees the maximum cleanliness.

Multiple Tests Ensure Superior Quality

We implement quality control procedures and use multiple testing devices to ensure that our products can meet the ISO 9044 standards. We try our best to make every filtration product have best flow rate, accurate filtration, high stability and easy cleaning to meet or even exceed our customers’ expectation.

01

X-ray fluorescence analyzer is used for raw material component analysis (XRF – material analysis).

02

Tensile strength tester is used for testing mechanical performance of materials and products.

03

Camera inspection table can test broken wires or dislocation and correct these defects timely.

04

Use computer-aided tools in production to measure the opening and distribution of grids.

05

Bubble point test is used to check the integrity of filter element structure and its maximum aperture.

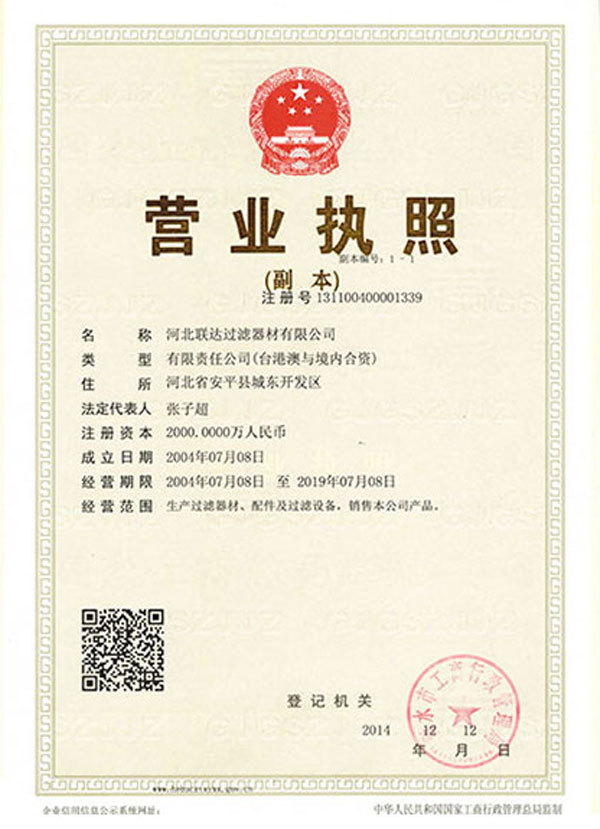

Certificates

We have passed ISO 9001 certification and continue to improve our techniques and introduce production equipment. We implement strict quality control throughout the whole production process.

Hebei Lianda Filter Equipment

Office: +86-311-89107778

Factory: +86-318-7529090

E-mail: marketing@lianda-filter.com

Website: www.liandafilters.com

Request Quote